- Details

- Hits: 606

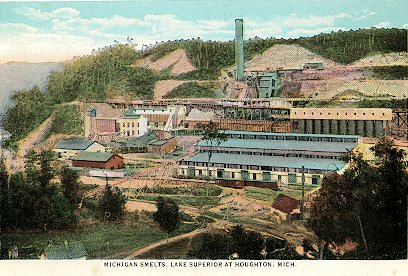

Location: Michigan Smelter, Cole's Creek, MI

The Michigan Smelter was a copper ore smelting facility located on the Keweenaw Waterway, 2 miles west of Houghton. It was placed into operation in 1904, jointly operated by the Copper Range Company and the Stanton group of mines.

The Michigan Smelter was a copper ore smelting facility located on the Keweenaw Waterway, 2 miles west of Houghton. It was placed into operation in 1904, jointly operated by the Copper Range Company and the Stanton group of mines.

Several mills sent stamped copper ore to this facility for smelting into pure copper, including the Champion, Baltic, Mohawk, Trimountain and Wolverine mills via the Copper Range railroad. Product from each mine was kept separated.

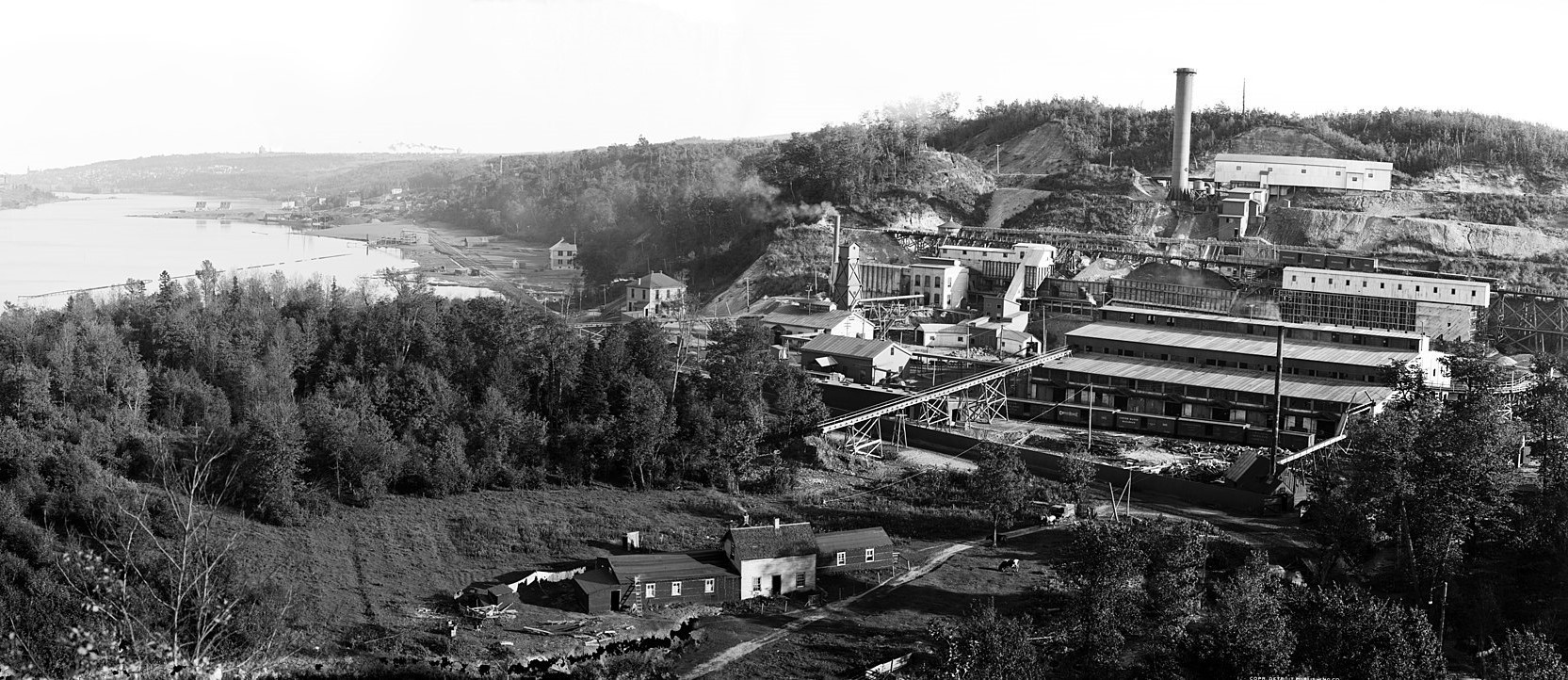

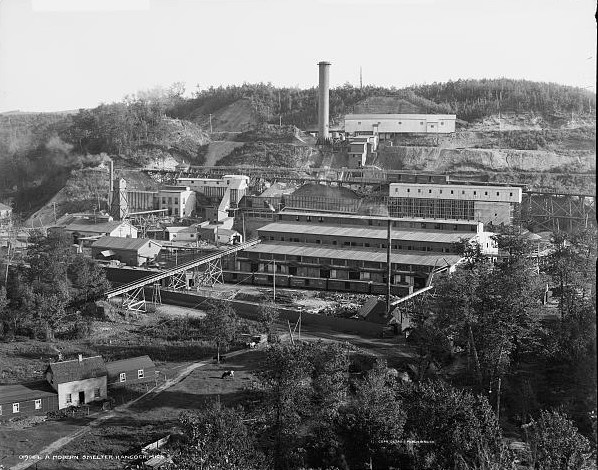

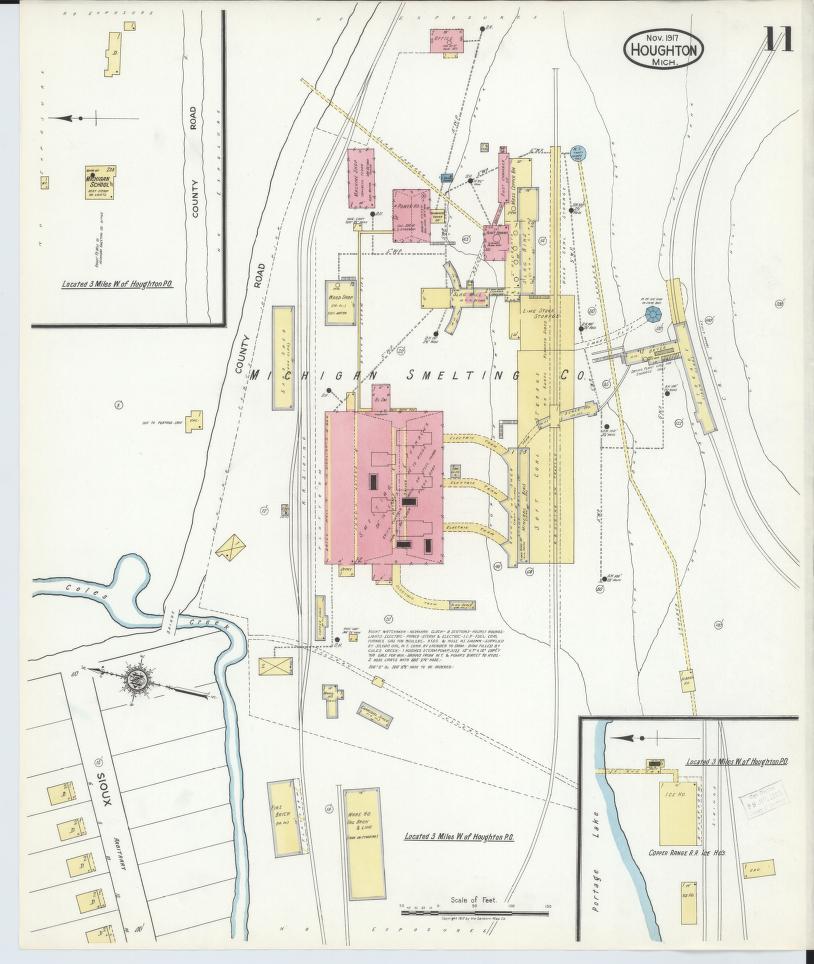

Photo info: Top, a colorized postcard view of the Michigan Smelter near Houghton. 2nd and 3rd images, views of the Michigan Smelter along Portage Lake canal. [LOC Collection]. 4th image, a map of the Michigan Smelter in 1917. [SBM-1917] 5th image, loaded flat cars with copper ingots at the Michigan Smelter. [Robert Platt, UMW collection]

Notes

The smelter was reached from the COPR Houghton Yard using a short branch line (Cole's Creek branch) along the Portage Lake canal. 1915 maps suggest that the upper side of the smelter appears to have been reached via a switch back on the west side of the complex.

Ore was brought from the mills near Freda to Mill Mine Junction, then down to the smelter. There were many railroad trestles on the site at all levels. Ore from the Mohawk mine, north of Calumet, was brought here by the Copper Range railroad over the Portage Lake lift bridge and into the Houghton Yard, west of downtown.

A dam on the smelter site, formally used by the old Atlantic Mill, was reused by the smelter as a water source. Operations at the Michigan Smelter ceased in 1948.

Buildings on site included an office and lab and were heated by exhaust steam. There was also a warehouse and two 150 ton railroad track scales. [Wiki] Finished product was brought to Houghton for loading on lake freighters or into box cars.

This was the first smelter in the region to use gravity in its processing, with ore loaded at the top. Other smelters in the area were built on flat ground. The smelter could handle 90 million tons annually. This smelter used separate melting and refining furnaces instead of performing both operations in one furnace. [HAL]

Most refined copper was transported from the smelter in ingots one mile to the Copper Range docks in Houghton and then out by lake boats. Coal and coke was received at these same docks and transported by rail to the smelter. [HAL]

It was noted in 1905 that this plant was the first of its kind south of Portage Lake. [DFP-1905-0617]

The Michigan Smelter generally shipped refined copper by boat from April to December, and by rail when Portage Lake and the Sault locks were frozen.

Time Line

1903. The Stanton-Paine group of mines incorporated the Michigan Smelting Company and began a plant on Portage Lake west of Houghton, and west of Cole's Creek. The works here would smelt copper rock stamped at the Copper Range mills near Freda, as well as other Stanton-affiliated mines such as the Wolverine, Mohawk and Atlantic mining companies. It also processed ore from the Winona and Michigan mines. The Stanton group held 8,000 shares of this operation and the Stanton-Paine group held 12,000 shares. [HAL]

1903. December. The exterior of the office building at the Michigan Smelter has been completed and work is under way on the interior. It is a commodious brick structure, two stories high. The structural iron work on the smelter building is about ¼ erected and the work is progressing steadily. The exterior masonry work on this building was completed some time ago, and as quickly as the iron work is done it can be roofed and will then be enclosed so that the interior masonry work, consisting mostly of the installation of the furnaces, can be carried forward. The structural iron work on the cupola building, which is not large, is almost completed. The powerhouse and warehouse, the two completed buildings, are being occupied, the latter with furnace brick and other material, and the former with the smelter engine, which arrived recently. It is the intention to have the smelter completed by July. [DFP-1903-1228]

1904. June. Two furnaces are in blast at the new Michigan Smelter on the south shore of Portage Lake. They will treat Trimountain mineral exclusively until the first of next month, when the remaining furnaces will be blown in and mineral from the Mohawk, Wolverine, Atlantic, Champion and Baltic mines will be smelted. [DFP-1904-0622]

1905. The plant of the Michigan Smelter Company is now in complete shape for the refining of the mineral from the Mohawk, Atlantic and Wolverine properties. [DFP-1905-0331]

1905. Tons of molten copper goes through the refining process, coming out in plates about 12" square and 1.5" thick. Most of this goes to the Detroit Copper & Brass Rolling mills, one of the largest consumers of copper in the United States. At the Smelter, the saving of labor has gotten down to a science. [DFP-1905-0725]

1906. The Michigan Smelter is now treating 5.5 million pounds of mineral monthly. This product comes from the Baltic, Trimountain, Champion, Mohawk, Wolverine, Atlantic and Michigan stamp mills. The plant is working perfectly. [DFP-1906-0217]

1910. A coal boat, the Harold Nye, will arrive in Houghton tomorrow with a consignment of special coal for the Michigan Smelter. The Schuylkill left Houghton yesterday east bound with a cargo of Copper. [CN-1910-1103]

1910. Nineteen cars of copper were shipped last week from the Michigan Smelter to Buffalo over the Copper Range. This is an unusual shipment and makes a good beginning of the annual copper shipments by rail. Since the steamer Alva cleaned up the copper stored on the docks of the company, the copper has been shipped entirely by rail from the smelter. [CN-1910-1208]

1944. A fire started in the coal, limestone and flux building at the Michigan Smelter during an electrical storm. The Houghton Fire department assisted by the Michigan Smelter fireman, did an excellent job in keeping the fire under check with minimum damage. [IDG-1944-1116]

1947. The Michigan Smelter is leased to the Lake Copper Refining Company. The structure was raised by 1952. [MIS-2024-1]

Bibliography

The following sources are utilized in this website. [SOURCE-YEAR-MMDD-PG]:

- [AAB| = All Aboard!, by Willis Dunbar, Eerdmans Publishing, Grand Rapids ©1969.

- [AAN] = Alpena Argus newspaper.

- [AARQJ] = American Association of Railroads Quiz Jr. pamphlet. © 1956

- [AATHA] = Ann Arbor Railroad Technical and Historical Association newsletter "The Double A"

- [AB] = Information provided at Michigan History Conference from Andrew Bailey, Port Huron, MI