- Details

- Hits: 3261

Plant: Omega Portland Cement, Mosherville, MI

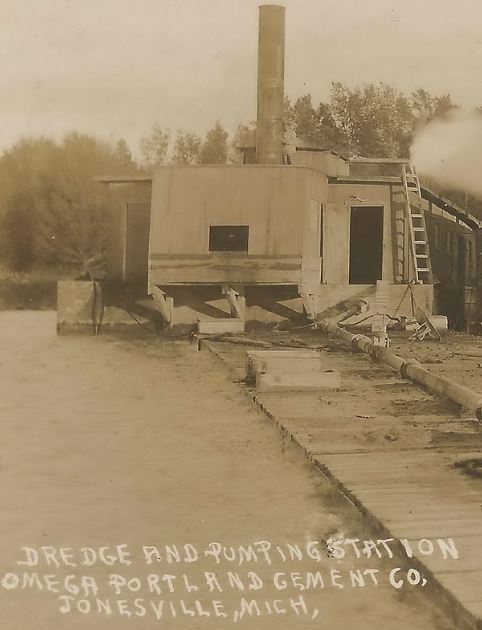

Photo Info: A dredge and pumping station at the Omega Portland Cement Plant near Jonesville, MI.

Notes

The plant stands near Cobb's Lake, on the Fort Wayne branch of the L. S. & M. S. Railway. This lake is one of a series of small lakes at the headwater of the Kalamazoo River. In the near vicinity are Hastings, Johnson, and Mosher's Lakes, and many large areas of marsh. All by actual tests and explorations have been found rich in marl deposits of an excellent quality. The discovery of marl has been the means of making a busy little village in the midst of what was once worthless soil. This is only a type of what is occurring in many places in our State. Northeast of Jonesville there are many lakes of this same character. Near Hanover, Moscow, Duck Lake and Addison Lake are lands rich in marl deposits. At Coldwater, Quincy, Bronson, Union City and Sand Lake extensive deposits occur and four of these places have successful plants in operation. Spencer Lake, some miles east, has also a marl bed. This region within a radius of less than fifty miles is especially favorable for extensive cement manufacture because of the abundance of marl and clay.

The plant of the Omega Company has a daily capacity of 700 barrels. The buildings are of brick and steel, and the storage house of cement concrete. The power house is 80x160 feet, containing a 750 horse-power engine, air compressors, pumps, dynamo, etc. The largest building or wet end department is 80x200 feet, and here the handling of marl and clay takes place. The marl is taken from the lake, which is 400 feet east of the mill, by a large steam dredge, and the beds of marl run to an average depth of 50 feet. The lake is one-half mile in length and one-quarter mile wide, being filled along the shore with much plant material. At the center of this lake a depth of 40 to 60 feet is found. For convenience in handling the marl the lake has been slightly lowered by dredging the outlet. The slimy marl taken from the lake bottom by the dredge is deposited in horse cars, skips or buckets, with a capacity of one cubic yard, and drawn to the conveyor shed, 30x130 feet, where the marl is elevated and conveyed by trolley and by automatic dump in skips dropped into the stone separator, which disintegrates the marl and relieves it of all sticks, grass and stones. In this building the clay, which is shipped in from Millbury, Ohio, is pulverized by passing through a dry pan, dried and weighed, and elevated to the mixing floor, where with the marl coming from the stone separator is mixed with the clay, forming a mud or slurry and passes to the pug mills. The Omega Company also have a clay bed one and one-half miles northeast of the works, which matches the clay brought from Millbury, and which they use at times when weather and roads will permit of transportation economically. [GSM]

Time Line

Bibliography

The following sources are utilized in this website. [SOURCE-YEAR-MMDD-PG]:

- [AAB| = All Aboard!, by Willis Dunbar, Eerdmans Publishing, Grand Rapids ©1969.

- [AAN] = Alpena Argus newspaper.

- [AARQJ] = American Association of Railroads Quiz Jr. pamphlet. © 1956

- [AATHA] = Ann Arbor Railroad Technical and Historical Association newsletter "The Double A"

- [AB] = Information provided at Michigan History Conference from Andrew Bailey, Port Huron, MI