- Details

- Hits: 3399

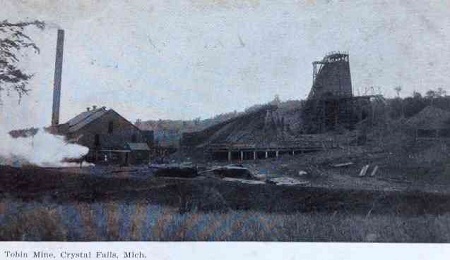

Mine: Tobin Mine, Crystal Falls, MI

Began → Tobin Mine → Became

Operated from 49+ years.

From: 1901

Location: SW Section 30 of T43N-R32W

Owned by: Republic Steel Corp.

Produced: Iron Ore, semi-hard, reddish-brown, high phosphorus. Crushed.

Method: Underground, by sub-level stoping method. Depth: 1,783 feet. Worked in conjunction with the Columbia Mine. Some open pit mining.

Railroad connection: C&NW to port of Escanaba. MILW.

Until:

Lifetime Production: 1901-1950 shipped 4,630,052 tons.

Notes

The Tobin Mine was located in Crystal Falls in Iron county. The mine was originally worked in 1891 and began producing heavily in 1901. Shipments continued periodically until 1960. The mine was worked jointly with the Columbia and West Columbia mines nearby. The mine site is about 1 mile southwest of downtown Crystal Falls.

Location: In the southwest part of Section 30, T43N-R32W. About 160 acres. The mine lies in the south half of this area and the main shaft is actually in NE-NW Section 31.

Coordinates: N46.5.12, N46-5-38, W88-21-24 and W88-22-1. [MINDAT]

Photo Info: Top, the Tobin Mine in 1911. Bottom photo, a major cave in at the mine, date unknown. 2nd photo, [MINART]

Time Line

1901. Fires were started under the boilers at this mine last week and at present half of the water is (pumped) out of the mine. The first work will be to enlarge the upper or old portion of the shaft to the same size as the new part sunk last year. The Milwaukee Road has a spur surveyed to the property and the C&NW's Columbia mine spur runs within twenty rods of it so that there need be no delay on account of a lack of facilities. [DD-1901-0427]

1903. The Corrigan-McKinney Mining company is laying out a new town at the Tobin mine, near Crystal Falls. Streets and alleys have been surveyed and the construction of a considerable number of houses will be started in the near future. [BHN-1903-0530]

1905. A company of about 25 men arrived to work on the St. Paul grade from the Tobin to the Dunn Mine. [DD-1905-0513]

1905. Corrigan, McKinney & Co., have the most complete and modern plant at the Tobin mine as to be found anywhere in the peninsula outside of the copper country. For nearly a year a program of improvement has been carried on and, in conjunction with surface improvements, the underground workings and the shafts were being put in shape commensurate with what was to be on top. The work of both is completed.

Beginning at the power end of the new engine house are four 125 h.p. boilers of high pressure type carrying as high as 150 lbs. of pressure. These boilers are horizontal type and every improvement known as been taken advantage of in the setting. An interesting part of the equipment is the economizer connecting the boiler with the big stack. In this economizer all of the gases and combustible material in the smoke are gathered and turned to the heating of the feed water. It is the first of its kind in use in these parts and is proving wonderfully saving upon fuel. Compared to the old feed water of 200 degrees, the new device is heated to 300 degrees.

The engine is of the Nordberg manufacture, is first motion with drums ten feet in diameter. The installment of this hoisting plant followed shortly after that at the Great Western that the operators were able to avoid any short coming found in the Western plant and thus the Tobin plant is as perfect as it could possibly be got (sic).

Standing beside this mammoth hoist is the big Imperial Type Rand compressor, capable of handling thirty drills. The shafts are fitted with safety appliances for the handling of men, timber, etc. This cage is pulled by a separate engine and hoist.

The new electric haulage has been ordered and is expected at the mine shortly. It is manufactured by the Jeffry Manufacturing company. The motor is of five ton capacity and is the very latest that can be had. After installation, the Tobin will begin to put out ore at a rate never dreamed of before for a Crystal Falls property. It is expected that at least 2,000 tons per day will be put out. [DD-1905-0930]

1910. The crew of workmen to perform the labor on the lowering of the grade of the Tobin mine spur are housed in boarding cars at the North-Western depot. [DD-1910-0514]

1911. The Tobin Mine has been opened to a depth of 1,100 feet, mining now to the eleventh level. From this level a winze has been sunk another 125 feet and crosscutting is now in progress to the shaft, thus making the twelfth level. This mine is electrically equipped, having electric haulage on the stockpile and underground.

The main shaft is 6’ 6”x22’ inside measurements, and four compartments. The main hoist is a twin Corliss Nordberg 20”x48”, first motion. The man and timber hoist is a Marinette 16”x20”, geared. The compressor is the Rand Imperial type of twenty-five drill capacity. The boilers are horizontal return tubular, four in the battery, with a total of five hundred horse power. At this plant the Green Fuel Economizer has been installed. Underground the water is handled by a Prescott triple expansion pump of 750 gallons capacity, with a Prescott compound of 500 gallons capacity as a relay. All the ore hoisted is crushed. [LSMI-1911]

1913. Orders were received from headquarters to close down the Tobin mine and preparations were began at once to enforce the orders and on the evening of the same day the men were laid off. The Tonin has a large pile of stocked ore and with what the other mines of the company are producing together with this pile at the Tobin the orders for the season will be filled. The news came as a big surprise to everyone, as the Tobin is one of the big mines of the city, employing several hundred men who are now, mostly, out of work as a result. Many of the men and especially those who have families dependent upon them, will be given work at the other mines, the single men being left to shift for themselves.

The pumps will be kept going for a while, until further information can be received as to the outcome of the property. Outside of the Bristol mine, the Tobin is one of the biggest ore producers in the county, so it is hoped by all that the shut-down is only temporary. [DD-1913-0729]

1915. October. The Tobin mine, which was shut down in July, 1913, will soon become an active producer again. When the mine was suspended two years ago the pumps were stopped and the mine allowed to fill with water, after which the shaft was sealed up. Recently orders were issued to get things in readiness around this mine for the reception of boilers get get the water out old the shaft. [DD-1915-1002]

1916. C&NW builds a new interchange yard at Tobin mine. [MCR-1916]

1916. The water in the Tobin mine rested yesterday morning just 20 feet below the 11th level of the mine. The total depth at that time was 1,108 feet and there was left 107 feet. The average progress is 9-feet per day so that 11 more days are needed to complete the watering job. The main shaft rests at the 12th level. Another level, the 13th, has opened up but it was opened by means of a winz sunk within the ore body. To unwater this level a pump will be placed on a cage in the winz and as the water lowers the cage will be lowered until the bottom is reached.

By Monday there will be 200 men at work in the mine and 100 more will be added just as soon as the 13th level is free of water. The Tobin operators say they have had no trouble so far in getting all of the men they want; that their only limit is housing capacity. It is probable that when the Odgers mione is opened more houses will have to be built at the Tobin to accommodate the number of workmen that will be required. [DD-1916-0205]

1916. The new switching arrangement entered into last year between the Milwaukee and the North-Western roads is in effect in the Crystal Falls District. By virtue of this arrangement the MILW switches all of the cars for the Tobin, Dunn and Carpenter mines and the C&NW all cars for the Balkan and Judson mines (near Alpha).

The C&NW empties for the Tobin, Dunn and Carpenter are pulled to the Odgers junction where they are left in the yard and a Milwaukee engine picks them up and distributes them to the respective mines. When they are loaded, the MILW engine hauls them back to the place where they were secured and there they are left for the C&NW engine.

The MILW is maintaining seven engines here to handle the business and the C&NW has fully as many. The arrangement on the MILW is somewhat different than on the C&NW. On the latter road, there is a yard master and switch men, but with the MILW all employees are in the train service, the crews shooting right out for Channing as soon as their trains are made up.

1917. The Milwaukee road was operating a snow plow on the Tobin branch last Saturday and got stuck in the snow. On Monday and Tuesday, they had gangs of men and a big engine trying to get the plow out but were unable to budge it. On Tuesday an extra large chain was hitched onto the plow and attached to the engine. After making the chain taut the big engine put on power and pulled the chain to pieces as if it was twine. Shovelers worked all day Wednesday and finally extricated the plow. [DD-1917-0324]

1937. Since the closing of the Tobin mine by Republic Steel, a number of men have been transferred to other districts, including Bessemer and the Ironton Mine. The Tobin mine was the last active property in Crystal Falls [BHN-1937-0416]

1949. November. At the Tobin mine, 180 men went back to work today on the heels of a settlement between the Republic Steel Corporation (which operates the Tobin) and the CIO-United Steel Workers on the controversial pension-insurance program. Like other mines in Iron County, the Tobin suspended operations on October 1. [EDP-1949-1110]